“Due to a switch malfunction, our train’s onward journey will be delayed.” Most rail travelers have probably heard this announcement at some point. In fact, switches are among the most complex and failure-prone elements of railway infrastructure, posing significant challenges for maintenance. Deutsches Zentrum für Schienenverkehrsforschung beim Eisenbahn-Bundesamt (DZSF/The German Center for Rail Transport Research at the Federal Railway Authority) is actively addressing these challenges. A large-scale research project is examining the potential of digital and data-driven maintenance for switch technology.

Switches are essential for flexible route planning and efficient rail network utilization. They allow trains to change direction, cross tracks, and optimize operational procedures. Switch technology is complex and maintenance-intensive, requiring them to withstand significant dynamic loads. Unsurprisingly, switch technology is costly—both in terms of acquisition and maintenance.

Germany’s approximately 65,000 switches are inspected at fixed intervals depending on their load. These inspections include visual checks, functional tests, and measurements of critical components such as point machines, actuators, and frogs. Ideally, components are replaced based on findings or experience before wear leads to malfunctions.

However, these processes remain highly labor-intensive, meaning that a shortage of skilled workers, an aging infrastructure, and high network utilization are causing maintenance backlogs and an increasing number of failures. Approximately 20 percent of train delays in Germany can be attributed to switch malfunctions

From Reaction to Prevention: Switch Maintenance 2.0

“We need new technological and organizational approaches to ensure effective switch maintenance,” says Axel Simroth, project lead at DZSF. He coordinates the research project on digital and data-driven switch maintenance, which aims to continuously monitor switch conditions and detect potential issues before they arise. The objective: extending switch lifespan, increasing infrastructure availability, and reducing costs.

Four Partners, One Goal: Data-Driven Maintenance

To achieve these ambitious goals, the DZSF has commissioned a consortium of four project partners, led by AXO Track GmbH, which has been working on the project since October 2024.

- AXO Track GmbH (Consortium Leader)

AXO Track GmbH, based in Berlin, develops sensor-based monitoring systems for predictive maintenance of existing railway infrastructure.They support the maintenance of critical railroad infrastructure by providing real-time data that can be integrated into the IT infrastructure of railroad companies.

- Fraunhofer IVI

The Fraunhofer Institute for Transportation and Infrastructure Systems (IVI) has been a pioneer in the digital transformation of public transport for over 20 years. At its Dresden and Ingolstadt locations, it develops innovative mobility, energy, and security technologies, focusing on vehicle and drive technology, intelligent transport systems, and digital business processes.

- IZP Dresden

The Engineering Company for Reliability and Process Modeling Dresden (IZP Dresden) supports engineering tasks related to RAMS (Reliability, Availability, Maintainability, and Safety), LCC (Life Cycle Costing), and data analysis. IZP specializes in creating RAM and safety assessments, predicting reliability behaviors and lifecycle costs, and optimizing maintenance processes.

- Weichentraining Horn

Weichentraining Horn is a certified training provider for switch technology. The company has extensive expertise in signaling and track technology and serves numerous infrastructure operators, switch manufacturers, and transport companies worldwide.

The project is scheduled for completion in March 2027.

Smart Switches: The Path to Predictive Maintenance

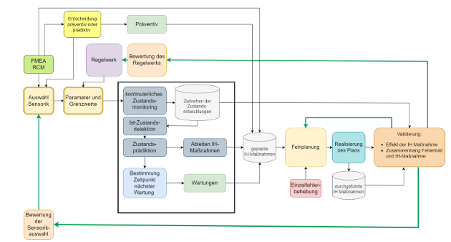

Initially, the project – consisting of four work packages – will involve an overview of the potential and challenges of new technologies in switch maintenance and servicing, led by Dr. Ute Gläser’s team at Fraunhofer IVI. The IZP, under the leadership of Dr. Jung, is conducting a comprehensive analysis of the frequency and causes of switch failures as well as the maintenance activities carried out.

One objective is to identify components where sensor installation is particularly beneficial in preventing malfunctions. Additionally, reliability analyses (distributions and MTBF values) will be performed at the component level.

From these analyses, requirements for digital and data-driven maintenance will be derived. Ute Gläser explains: “An important step is developing and validating a sensor concept that accounts for local environmental parameters. Our iterative development process considers criteria such as secure communication, system integration interfaces, and analysis and diagnostic software.” For DB InfraGO, the practicality of different systems is crucial: maintenance teams must be able to quickly and clearly identify switch issues based on the data.

As part of Work Package 2, the AXO team will conduct an experimental feasibility study. In collaboration with DB Weichentechnik, 50 switches will be selected and equipped with sensors in the frog and point areas. These “problem switches” have a high failure rate and are scheduled for maintenance in the coming months.

Data, Analysis, Solutions: How Partner Activities Provide Clarity for Switch Technology

Starting in Q3 2025, Work Package 3 will develop a digital and data-driven maintenance concept for switch technology. The focus will be on the complete process chain, from data collection and processing to failure prediction and assessment, as well as deriving maintenance measures and optimizing their planning.

Looking Ahead: Will Digital Switch Maintenance Become the Standard?

This project goes beyond pure research—it aims to provide concrete migration paths for gradually integrating the developed solutions into Germany’s railway network.

Even today, the potential of such approaches is evident: sensors and predictive maintenance could lay the foundation for a future-proof railway system that meets the growing demand for sustainable mobility. A widespread rollout promises improved punctuality, safety, and cost-efficiency in rail transport.

Oliver von Sperber states: “Digitized maintenance is a key lever in modernizing rail transport and addressing the skilled labor shortage. With our expertise and innovative collaboration within the consortium, we are laying the foundation for a more sustainable and reliable railway system in Germany.”

Follow us on LinkedIn to stay updated on the next steps of the DZSF research project on digital and data-driven switch maintenance.